He came to the interview from his morning boxing training still with plenty of energy and in good spirits, although not everything he said later was happy. Robert Kiml, the new – and first Czech – president of Kolín-based Toyota Motor Manufacturing Czech Republic since June, has made no secret of his reservations about the European green agenda. He advocates technological neutrality in the transition to zero-emission mobility and says customers must have a choice. He does not doubt that petrol and diesel engines will come to an end; the transformation has already begun in Kolín, but so far it has taken the form of hybrids. The fight over which European Toyota factory will produce battery electric cars is just beginning.

When I see those boxing gloves and I know that it’s not just a prop, but that boxing is an important part of your life, I can’t help but ask: Are you a fighter?

I’m definitely a fighter. But the main reason I go to boxing is because my personal coach recommended the sport to me a few years ago. He said that I had an awful lot of energy and that it would be best if I always went to the gym in the morning, because the excessive energy could cause negative reactions in some of my subordinates. So I started playing tennis and running, and I’ve been boxing for the last six years. I love it.

But you will certainly have enough energy left over during the day. It must be quite a change for everyone in the company, since the previous president of the company, Mr Koreatsu Aoki, who was rather discreet and calm, as I had the opportunity to get to know him, was succeeded by an enormously energetic manager.

Each person is an individual and each new manager means a certain change. I have a different approach from my predecessor, but I try not to make any dramatic changes. We have a shared vision, we want to retain the know-how of the Japanese company, but with my arrival there is a certain shift towards a more European style of management. We also have to respond to the fact that there is a new generation that sees the world in a completely different way. Our generation still remembers that there was a lack of something, the younger generation no longer does. Something is resonating here that no one knew twenty years ago: work life balance, working but living at the same time.

Money is not the main motivator for young people today, so we need to come up with a lot more motivators and benefits. But in terms of focusing on the employee, that is what Mr Aoki has focused on, so there will not be a big change here. Where there should be changes is in empowering middle management, empowering them to be decision makers and also empowering them to be accountable and independent.

Who gets an electric car

You are the first Czech president in Toyota’s more than 20-year history in the Czech Republic. At the same time as you took over this position, there were a number of changes in other subsidiaries in Europe. Does this mean anything?

Nothing major, nothing pre-planned, just more things coming together. A few colleagues retired, a few colleagues went back to Japan, so there were a few changes.

So nothing has happened in the European network yet in terms of the transition of production plants to electric mobility? Apart from the Czech Republic, Toyota also has production in France, Portugal, the UK and Turkey, but there is talk that it will not be possible to rebuild all of them to produce EVs.

Of course, converting a factory that produces cars with internal combustion engines to produce emission-free vehicles is very difficult, it costs more than if you built a new factory. So it’s clear that it’s not worthwhile everywhere. Different car companies approach it differently. For example, you can go in the same direction as Tesla – you can build one gigafactory where you can make half a million or a million cars, and the need for a large number of production plants falls away.

Is this scenario realistic for European Toyota as well?

For the time being, Toyota has no plans to close its current production plants, but it is certain that some optimisation will have to take place in the future.

What kind of future are we talking about?

By 2035, everything must be implemented, because after that year, no combustion-engined cars will be allowed to be sold on the European market. Since the financial resources for the rebuilding will be enormous, the individual plants will be fighting over who will survive.

“Converting a factory to produce emission-free vehicles is very challenging. So it’s clear that it’s not worth it everywhere.”

Does Kolín have a chance?

I’m sure it has a great chance. It has good people, it works well. We managed to successfully start production of the Yaris and Ayga X in record time, and the Czech Republic is a great location with lots of good suppliers. Personally, I believe that the future of electric cars is here and I will do everything I can for it.

When do you think it will be decided?

We are in competition with France, Turkey, Poland and the UK. We reckon that a decision on the location should be made by the end of this year or early next year.

It has to be soon, because European regulation mandates a gradual drop in average CO2 emissions – which applies to all cars sold from a single manufacturer, next year the limit is reduced to 93.6 g/km (WLTP standard) of CO2 emissions per car sold in the EU. You already have to have a certain proportion of electric cars to fit the limits. We are now focusing on a certain transition stage, on hybrid technology. In general, from next year you will have to have at least one electric or plug-in hybrid for every combustion engine car to get to the required average emissions. If you don’t achieve that, you’ll pay a huge fine.

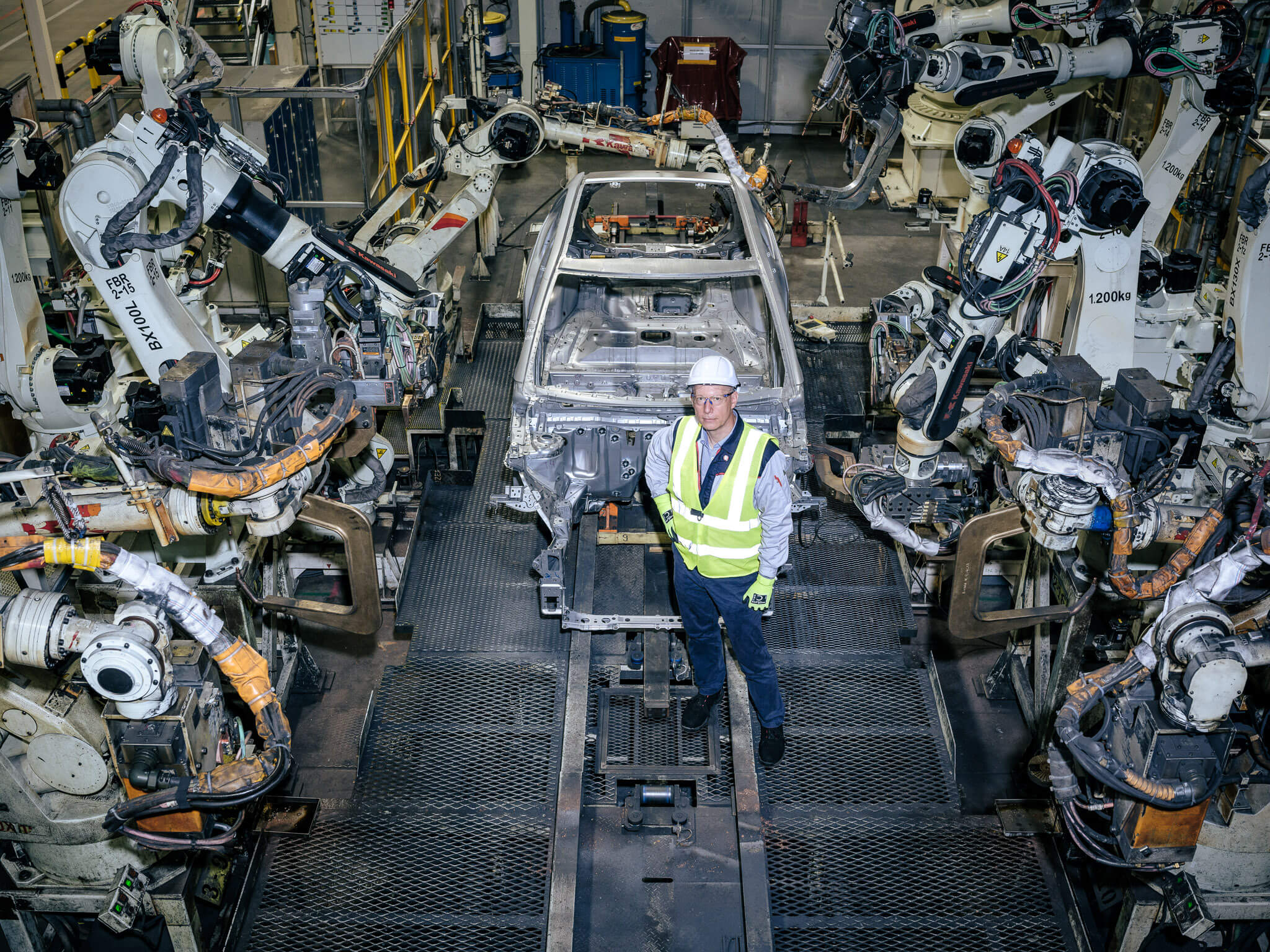

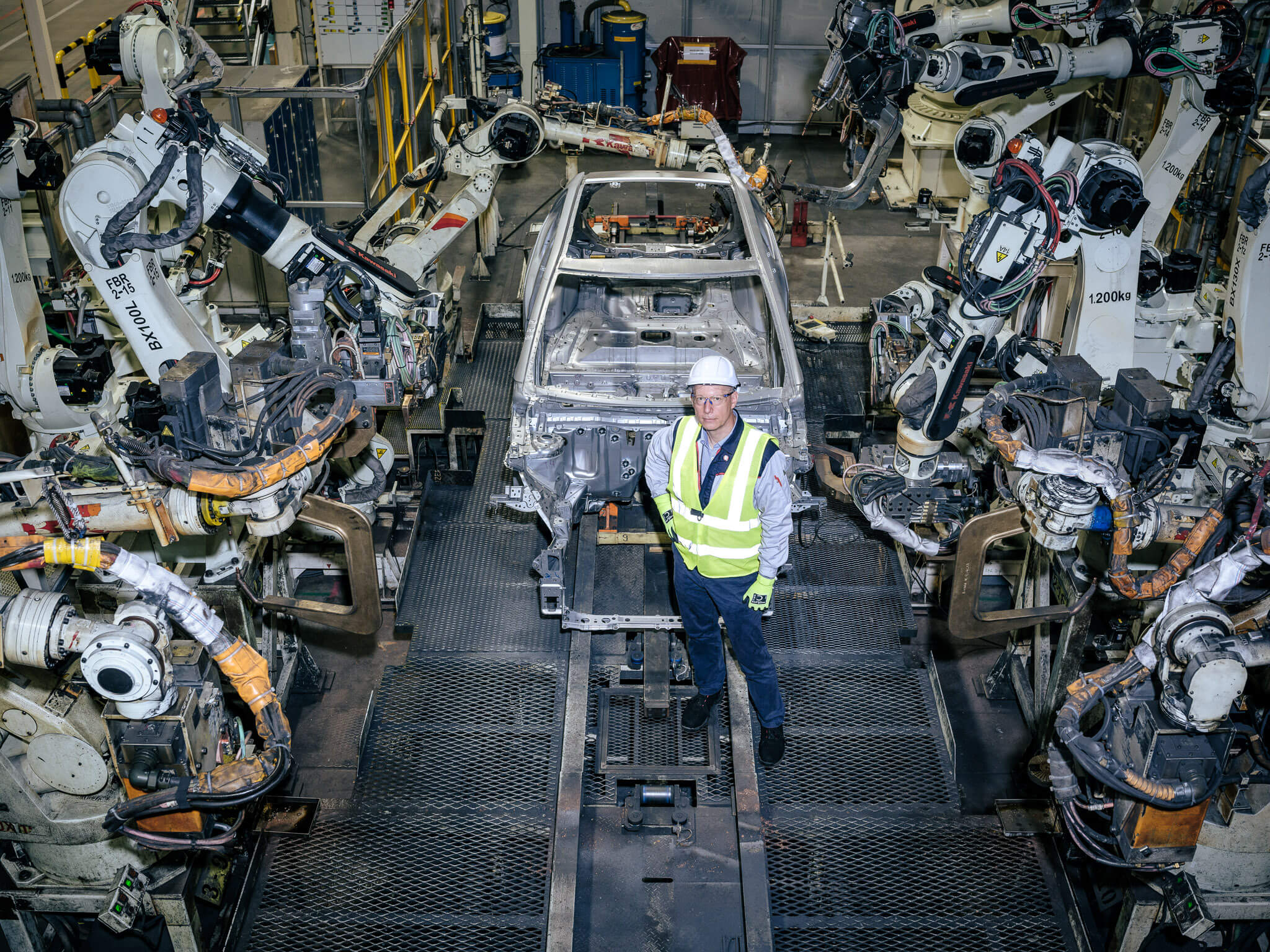

“Kolín has quality people and works well. We managed to successfully start production of the Yaris and Ayga X in record time, and the Czech Republic is a great location with lots of good suppliers. I personally believe that the future of electric cars is here and I will do everything I can to make it happen,” says Robert Kiml. | Photo: Pavel Šinagl

What kind of electric car will it be? Can you tell me more?

It will probably be a specific European model.

A more luxurious one, or more of a people’s car?

We’re aiming more for a vehicle for the general public with very good equipment already in the base, as is usual with Toyota. The luxury segment is represented here by the premium brand Lexus.

Where is the model being developed?

As it is a new technology, the basic development is taking place in Japan. As for the body, it is being developed in Europe, the design will be European.

You say that Czech Toyota has a chance to get this new production because it has skilled people and a good track record. What else speaks in its favour?

The location in the centre of Europe and the number of quality suppliers. We have a good reputation throughout Toyota, and within six months we have started production of two cars. We’re running at ninety-seven percent production efficiency. We have a good track record in terms of diversification, inclusion and other elements that are also being evaluated with a view to the future.

However, high energy prices and a potential shortage of workers stand in the way.

Yes, these are negative points. As far as high energy prices are concerned, they mainly affect our suppliers, while the impact on us in assembly is not so great. But high energy prices are a problem for all Central European manufacturers or suppliers.

Is there anything else that is currently bothering you? What do you need to solve at government level?

We would need to avoid constant restrictions on labour flexibility. We’re already struggling with the fact that, one: there are no people in general, two: a lot of them don’t want to work in manufacturing, and three: we have an ageing current generation. In addition, new regulations are constantly coming in that are even more stringent than the EU regulations, thereby reducing the flexibility of the labour market. On top of that, we have some old rules from the Communist era, under which, for example, you cannot order overtime unless you have serious technological or other problems. So, on the one hand, we cannot hire people because they are not there, but neither can we work flexibly with those we do employ.

To mandate overtime without serious reasons – there’s probably not a lot of receptivity to that kind of change.

Probably not, but I have to say that it is very difficult to operate in this way if we do not want to use agency workers.

Hybrid Aygo

Let’s go back to production. You mentioned emission limits, which force companies to put emission-free cars into production, or at least cars with the lowest possible emissions. The emission limits apply to the whole company, in your case Toyota Europe. I would say that the Kolín plant rather improves the balance sheet of the whole company, even if it does not produce clean electric cars – by producing smaller and therefore greener cars.

Definitely. But in the future, production in Kolín must change. We currently have only one hybrid model, the Yaris. In addition to that, we make the Aygo with a litre engine, where it hasn’t been worth changing yet because it was consuming around four litres. If we add a hybrid engine, CO2 emissions will fall, but the price of the car will rise because of the installation of the electric motor. However, as has been mentioned, the need to reduce CO2 emissions is forcing us to reconsider this decision.

How much will hybrid technology make the car more expensive? The advantage of the Aygo was that it was small equals cheap. Is it worth it?

Until recently, it hasn’t. You are right that it increases the price, we can talk about two to four thousand euros. This can have an impact in markets where price plays a big role. On the other hand, as you will have noticed, a lot of car companies have stopped making small cars because there is not much money to be made in such small cars. But when others left the segment, the market opened up for us. We still believe in small cars and we believe that even the more expensive Aygo will find its customers.

From this July, all cars registered in the EU must have additional mandatory assistance systems. This is part of a European Commission regulation known as the new General Safety Regulation 2. These include emergency braking assistance, lane departure warning, drowsiness detection and more. Additional systems in the form of sensors and cameras must also be fitted in small cars. This has certainly also increased the cost of production. How much more expensive are cars with these systems?

This is the basic reason why many car manufacturers are stopping making small cars. The price of new cars has risen considerably with the increase in sensors and systems. In the past, the equipment and price of a car increased with size. The customer had a choice. Now all cars, regardless of size, have almost everything and the price has increased significantly. I’ll give you our Aygo as an example. 10 years ago the base price was somewhere around 190,000 crowns, now it starts at 340,000. Much of the increase is because of this.

“The price of new cars has risen considerably as the number of sensors and systems has increased.”

However, there are no changes to the production plans at Toyota Kolín at the moment.

No, we are not changing our plans, we are continuing to produce these models because they are popular and they are essential for Europe. We have 10 to 15 percent of the market in Europe with these models. More than half of our production, 55 per cent, are Yaris, the vast majority hybrids and in time they will all be hybrids. The rest are Aygas, where we are also considering adding a hybrid powertrain.

Unlike some other car companies, we still believe in hybrid technology as an intermediate step towards total zero-emission mobility – especially since zero-emission mobility is only supposed to take one form at the moment, and that is battery cars, which have their advantages but also disadvantages. Our hybrid technologies allow us to achieve the required CO2 limits even under the current stringent conditions. Toyota is of the opinion that more technologies should be involved, including hydrogen cells, but perhaps also hydrogen combustion. We think that the customer should be able to choose the car that suits their personal needs.

We see what is happening on the European market: electric cars that are not supported by the state are not selling as well as expected. A certain proportion of customers who wanted an electric car have already bought one, but there is a huge proportion of potential customers who have different needs in life – they do not live in a city, they commute far and they are not sure that an electric car will take them where they need to go. Until now, they have had a choice.

Toyota respects the diversity of people and their needs. So it wants to roll out more technology. But the infrastructure isn’t ready for that yet.

On the production line at the Toyota Motor Manufacturing Czech plant in Kolín, where the Yaris and Aygo X models are produced. | Photo: Pavel Šinagl

After the French partners left the original TPCA in 2021, there was talk that Toyota might eventually introduce some development in Kolín. Did it happen?

We don’t have development here at the moment, it’s still centralised in Brussels. In the meantime, a number of things have happened, mainly the covid pandemic, which has severely limited the functionality of individual companies, and there has been a new setup. Today we have a shared IT centre for European plants. I believe that in the future there will be more so-called production engineering.

But we are also starting other things. For example, in November we will take over some of the work of preparing cars not only of our brands for the dealer network, modifying them, adjusting them to customer requirements. We haven’t done that here before.

Moving car companies and China

What do you see as the biggest problem for you, for the automotive industry in the Czech Republic?

It is the aforementioned energy, which limits the localization of production of individual parts. Today it is cheaper to import them from Japan, Turkey or China. It may not be so visible now, but it will be an even bigger problem in the next few years. For new models, we select suppliers three to five years in advance and by that time we are already negotiating the price. If a local supplier is able to work more efficiently and reduce energy consumption, then they have a chance. But if it has 40 or 50 percent more expensive energy, then its competitive advantage is very small. Then it is worth importing parts from Turkey, for example, if we want to stay in Europe, where gas and electricity are much cheaper than here.

Toyota also has a plant in Turkey where the Corolla and Toyota C-HR are produced.

Turkey is increasingly popular among car manufacturers and their suppliers, as is Morocco or Egypt. Do you think that more and more capacity will be moved there?

The fact is that there are not as many restrictions as in the EU, there are not as strict environmental requirements, which makes production cheaper, and there is plenty of labour. These countries will definitely start to play a much bigger role.

European manufacturing will start to move to Africa and more and more Chinese manufacturers will come to Europe.

This is a logical parallel to what we have already seen twenty or thirty years ago, when Japanese and Korean companies started coming in. They started to manufacture here because of import taxes and logistics costs. Companies manufacturing on the European continent are subject to the same rules in terms of ecology or, for example, relations with employees as domestic companies here, Volkswagen, Skoda and others, so the playing field is level and it is fine.

“It is important to remember that the world is not just the US and Europe, and we should not distance ourselves from some continents.”

I wouldn’t oppose Chinese investment as long as their business is fair. In our country, the attitude towards Chinese companies is currently being modified based on a political perspective, it is different than a few years ago when we attracted the Chinese here. But it is important to remember that the world is not just the US and Europe, and we should not distance ourselves from certain continents.

As far as cooperation with Chinese car companies is concerned, some European companies are currently even expanding it. How is Toyota doing?

We produce around two million cars in China and we work with local suppliers there. It is also important to realise that China controls most of the sources when it comes to battery cars. So it is fair to say that the transition to electromobility without China and Chinese mineral resources, as the EU envisages it, is basically impossible.

What do you think about imposing tariffs on Chinese electric car imports because of state support for local car companies?

I have already heard that France is afraid of China imposing tariffs on wine, their main export. Imposing tariffs will only create further inequality in the market. Should we not instead be looking at giving some support to electromobility in the EU – like China. Then the playing field would be levelled. At the moment, there are strict regulations in Europe on the one hand and, on the other, a consumer who is not prepared for this and is – for the first time in history – forced to drive what the EU has chosen.

Who and what to support

How would you imagine the incentives? Should they be targeted at buyers or more at producers?

I am not a supporter of subsidies for purchasing. I think the support should be targeted at technology development, which would then be reflected in the price of the cars for the end customers. It is important to realise what we want to achieve, and that is emission-free mobility. However, if we also want to achieve customer satisfaction, we cannot force them to buy a type of car that might not suit them. And to change all their lifestyle habits at once.

We should focus on new technologies that are more advanced than the Chinese ones, and we should focus on making Europe self-sufficient and independent. At the moment, we are replacing our dependence on Russia, or Russian energy, with dependence on China just because we have decided to have battery electric cars.

So not sales promotion, no purchase incentives, but development support at European level, so much broader changes.

I will give you an example. In the US, when they found that the state was not able to provide everything in terms of investment in space technology, they supported the development of several private companies. The private sector can be more efficient and cheaper. With this approach, the United States has moved a long way forward. China has done something similar – it has supported companies in the development of electric cars, so they have a big advantage at the moment.

The European Union is not planning anything like that; each country has a completely different policy and a different approach to the Green Deal. The ideal would be for everyone to unite and also give more space to the private sector, which would fight for customers by developing different technologies. This means giving space for technological neutrality, which would also help to ensure diversity and reduce the need for certain critical resources.

“We should focus on new technologies that are more advanced than China’s and focus on making Europe independent and autonomous,” Robert Kiml said in an interview. | Photo: Pavel Šinagl

Do you see any possible change in approach after the election of the new European Parliament?

The European Parliament has changed a bit, but it has still remained very green and I don’t expect a dramatic change. Maybe a change in some of the parameters.

I would suggest that we go back to the basics – and that is the objective of reducing carbon emissions. On the one hand, we are focusing on that, but on the other hand, by producing batteries and other elements, we are raising emissions. If we do not have emission-free energy, the amount of CO2 produced globally is increased by that production. The EU puts itself in a position of being able to do everything, but its share of global emissions is 8%. So even if we immediately reduce emissions to zero and they do not increase elsewhere, it will only be an eight per cent reduction. At the same time, it makes European industry uncompetitive.

Technological neutrality

You mentioned technological neutrality. Toyota is a well-known pioneer of hydrogen technology, or fuel cell propulsion. Has there been a shift in development there, or is the Mirai still the representative of this drive?

Apart from the Mirai, we already have a hydrogen Hilux and even a hydrogen Yaris, and we are preparing to sell them. We are also testing a hydrogen-powered truck. We have hydrogen bikes, hydrogen scooters. We’re also starting up hydrogen stations to generate electricity. We have everything in place, but it’s a vicious circle. If you don’t have hydrogen filling stations, you can’t expect to sell hydrogen cars.

When I talked about what needs to be supported, apart from the development of the drives themselves, it is primarily the construction of infrastructure.

Is Toyota also trying synthetic fuel engines?

Yes. We are going down what we call the multi-functional route, where we want to have everything from hybrid cars to fuel cell cars to those burning hydrogen or synthetic fuels, or with other powertrains. And we already have all of that and we’re testing it. We want to meet the needs of all customers on all continents, not just European ones.

“Toyota is going down the so-called multi-functional route, where it wants to have everything from hybrid cars to fuel-cell cars to those burning hydrogen or synthetic fuels, or with other powertrains.”

What future do you attribute to hydrogen combustion?

It’s a huge opportunity to use internal combustion engine technology and operate emission-free at the same time. They can be used for large machines, for example, construction machines, in places where there is no possibility of connecting to electricity. You just need to bring a tanker of hydrogen.

Who will pay the future

We talked about the fact that even small cars with combustion and hybrid engines will be more expensive. More bad news for the automotive industry or for consumers may come in 2027, when fuel producers will have to buy emission allowances, which will make petrol and diesel significantly more expensive. So perhaps a certain part of the population will no longer be able to finance the running of a car and demand for vehicles with an internal combustion engine, which has been the only choice for this part of the population, will fall. In addition to this, there will also be other costs for people, which will be linked to other areas where emission allowances will also start to apply. What do you think this will mean in the medium term?

If we introduce allowances for everything, then prices will of course rise, and for everything. Even if it is only a few crowns for petrol/diesel, the higher logistics costs will be reflected in all goods. It will partly raise inflation and the citizens of Europe will no longer be able to afford many things. It will still be possible to buy an older car with an internal combustion engine, but they will no longer be able to afford petrol. This extremely rapid transition to a zero-emission economy is not entirely well thought out. The middle class, whose standard of living will be reduced, will pay for this whole change. The rich will not be affected and the poor will be poorer.

So we can expect demand for cars to fall?

It may fall if it is not transferred from private customers to companies. I think in the future cars will be used more intensively, for example in the form of carsharing. Such cars then have a shorter lifetime and will be replaced more often. But time will tell.

Robert Kiml graduated from Czech Technical University and then continued his studies in Japan. He remained at the University of A&T in Tokyo for four years as an assistant professor. His first Czech employer, and to this day his only employer, is Toyota. He joined Toyota in Kolín (then TPCA) in 2004, managing the paint shop operations and later the quality department. He also worked in the management of Toyota’s sister plant in Poland. Since 2017, he has been General Manager for Administration at TPCA, and Vice President for Production at TMMCZ. He was appointed President of TMMCZ on June 1, 2024. In the Automotive Industry Association of the Czech Republic he holds the position of Vice President.

Robert Kiml graduated from Czech Technical University and then continued his studies in Japan. He remained at the University of A&T in Tokyo for four years as an assistant professor. His first Czech employer, and to this day his only employer, is Toyota. He joined Toyota in Kolín (then TPCA) in 2004, managing the paint shop operations and later the quality department. He also worked in the management of Toyota’s sister plant in Poland. Since 2017, he has been General Manager for Administration at TPCA, and Vice President for Production at TMMCZ. He was appointed President of TMMCZ on June 1, 2024. In the Automotive Industry Association of the Czech Republic he holds the position of Vice President.

Contact

Next articles and interviews

Next articles and interviews

+ Show

Robert Kiml graduated from Czech Technical University and then continued his studies in Japan. He remained at the University of A&T in Tokyo for four years as an assistant professor. His first Czech employer, and to this day his only employer, is Toyota. He joined Toyota in Kolín (then TPCA) in 2004, managing the paint shop operations and later the quality department. He also worked in the management of Toyota’s sister plant in Poland. Since 2017, he has been General Manager for Administration at TPCA, and Vice President for Production at TMMCZ. He was appointed President of TMMCZ on June 1, 2024. In the Automotive Industry Association of the Czech Republic he holds the position of Vice President.

Robert Kiml graduated from Czech Technical University and then continued his studies in Japan. He remained at the University of A&T in Tokyo for four years as an assistant professor. His first Czech employer, and to this day his only employer, is Toyota. He joined Toyota in Kolín (then TPCA) in 2004, managing the paint shop operations and later the quality department. He also worked in the management of Toyota’s sister plant in Poland. Since 2017, he has been General Manager for Administration at TPCA, and Vice President for Production at TMMCZ. He was appointed President of TMMCZ on June 1, 2024. In the Automotive Industry Association of the Czech Republic he holds the position of Vice President.