The use of hydrogen in transport, like virtually all new technologies, has its uncritical supporters and staunch opponents. Moreover, the view of its future changes over time – again from enthusiastic promotion and support to outright condemnation. Technically, and therefore soberly speaking, it offers very interesting and beneficial possibilities for reducing climate burdens, but at the same time its expansion will require huge investments.

Hydrogen is the lightest gas with great potential for environmental protection. But it is very rare in nature and most of the world’s hydrogen production comes from fossil fuels – mainly steam reforming of natural gas or oil. However, at the same time, large amounts of carbon dioxide are produced. Only the use of so-called ‘green’ hydrogen, which is obtained by electrolysis of water using electricity generated exclusively from fossil-free sources, makes environmental sense.

Use in transport: enthusiasm and disillusionment

Hydrogen is used in transport in three forms. The combustion of hydrogen generates a large amount of energy, so several car companies have tested combustion engines using hydrogen gas as a fuel. While this does not release carbon dioxide, it is not a completely emission-free process. The most widespread and most efficient use of hydrogen is in fuel cells to generate electricity to power traction motors in electric vehicles. Hydrogen is also the basis for the production of synthetic fuels (e-fuels) that could replace fossil fuels.

Hyundai Nexo Fuel Cell refuelling at the first hydrogen plant in Spain. | Photo: Hyundai

The use of hydrogen in transport has undergone dramatic changes in the last two decades – from widespread enthusiasm to almost complete abandonment. The same has been true of political support within the EU – from labelling hydrogen as the fuel of the future that solves all problems to claiming that hydrogen use in road transport makes no sense because it will be needed in other sectors, especially metallurgy, or for rail, shipping and aviation.

Fuel cells have a long history

The principle of fuel cells is to combine hydrogen and oxygen in the air to create electricity. The only emissions are water vapour and heat. Fuel cell cars have electric propulsion, but they make do with a much smaller battery, which only serves to compensate for the increased power requirements. Compared to battery electric vehicles, fuel cell vehicles have a much longer range, virtually the same as vehicles powered by internal combustion engines. Hydrogen refuelling is also faster than recharging batteries, again comparable to conventional fuels.

Since the 1970s, many car companies have been demonstrating experimental vehicles powered by electric motors powered by fuel cells. With the start of the millennium, it seemed that the future of transport would be linked to hydrogen. At the time, General Motors presented its fuel cell vehicles to the media, a Mercedes-Benz fuel cell car made a successful trip around the world (admittedly accompanied by a hydrogen tanker truck), BMW introduced a car with a hydrogen engine, hydrogen refuelling stations began to open in Germany, California and Japan, and hundreds of fuel cell buses were already in operation around the world. Honda in the US has made its fuel cell cars available to the public for trial runs and has been joined by General Motors. In 2009, the first experimental hydrogen-fuelled bus was also launched in the Czech Republic, and the first refuelling station was opened in Neratovice. It was also used for the presentation of Honda and GM vehicles.

Stellantis’ light commercial vehicle platform for fuel cell propulsion with longitudinally mounted hydrogen tanks. | Photo: Stellantis

With the rapid development of wind and solar energy, hydrogen production has been offered as an ideal solution to their unstable electricity supply. Plans have therefore emerged to combine solar and wind power plants with electrolyzers for hydrogen production.

But a few years passed and the fuel cell vehicle development programmes at Mercedes-Benz and General Motors came to an end, as did the development of hydrogen internal combustion engines at BMW. Even the Linde Group, which had been at the forefront of developing a network of refuelling stations, lost interest in promoting the use of hydrogen in transport. This was mainly due to the uncertain economic return on these extremely expensive projects at a time of emerging economic crisis. The plans for building electrolyzers thus remained only in fancy presentations.

New future

So there has been a shift away from hydrogen use in transport? Absolutely not, quite the opposite. Thousands of electric buses powered by hydrogen fuel cells are already running around the world, and they are far from being just test vehicles. Toyota and Hyundai are selling fuel cell passenger cars around the world, including in the Czech Republic, and BMW is moving closer to mass production thanks to its partnership with Toyota. The Stellantis Group has started production of light commercial vehicles with fuel cells and Renault is just a step closer to starting production.

Above all, however, fuel cells are being tested in practice by virtually all major heavy truck manufacturers, with many start-ups joining in. The use of fuel cells is now widely seen as the only acceptable solution for emission-free long-distance heavy goods transport.

Toyota Mirai fuel cell vehicles will provide transport during the Paris Olympics. | Photo: Toyota

More importantly, the necessary infrastructure is being built in many parts of the world, so that the use of these vehicles is already seamless in many areas and can be used for longer distances. At the end of 2023, there were 265 hydrogen filling stations in Europe, but 105 of these were in Germany. The problem is that more than two-thirds of these stations are only usable for passenger cars. On the other hand, the good news is that 34 of the 37 new sites opened in 2023 have already been adapted for heavy goods vehicles and buses.

In all colours

What has unfortunately not changed over many decades is the lack of hydrogen production in a way that does not burden the environment. Here, too, we are seeing progress, but not nearly as fast as was needed and predicted at the start of the millennium. If the use of hydrogen is to be truly beneficial to the environment, then it is essential that its production is truly climate neutral. But this is not the case – 98 per cent of global hydrogen production comes from reforming natural gas or oil, as this technology remains the most affordable option.

All of the world’s current hydrogen production would be enough to power 300 million fuel cell cars, about a third of the entire global fleet. There is therefore relatively enough hydrogen in the world to meet current needs. But most of this hydrogen is the wrong colour. That may seem like a contradiction in terms for a colourless gas. But hydrogen is classified according to how it is produced, or its emission footprint. Accordingly, it is labelled with different colours, although this labelling is not official and completely uniform (and to make things less simple, for industrial use, hydrogen cylinders are labelled red).

Solar Global has commissioned the first green hydrogen production in the Czech Republic in Napajedli. | Photo: Solar Global

In the future, green hydrogen, i.e. hydrogen produced by electrolysis of water without harmful greenhouse gas emissions using electricity from completely emission-free sources, should play a decisive role in the hydrogen colour rainbow. Electrolyzers use an electrochemical reaction to split water into hydrogen and oxygen. However, green hydrogen currently accounts for a negligible share of total production. Moreover, the rules for green hydrogen production are not entirely uniform – they are much stricter in the EU than in the US, for example, which can pose a problem for electrolysis equipment manufacturers. Just a small addition: hydrogen produced by electrolysis using solar energy is now also referred to as yellow hydrogen. Pink hydrogen (sometimes also referred to as purple or red) is produced by electrolysis using energy from nuclear sources.

Blue hydrogen is produced from natural gas by steam reforming, which combines natural gas and heated water in the form of steam. The output is hydrogen and carbon dioxide as a by-product. This means that a CO2 capture and storage system must be part of the process. This is why blue hydrogen is also referred to as low-carbon hydrogen.

Currently, the most common is grey hydrogen, which is produced from natural gas or methane by steam reforming, but without subsequent carbon capture. When black or brown coal is used in a similar production process, the hydrogen is referred to as black and brown.

Turquoise hydrogen is produced by a process called pyrolysis from natural gas to produce hydrogen and solid carbon, which can be permanently stored or further used. However, this production has yet to be verified on a large scale. In the future, turquoise hydrogen may be rated as low-emission if it is powered by emission-free energy sources.

White hydrogen is a naturally occurring geological hydrogen found in underground deposits that can be extracted by hydraulic fracturing. There is currently no production of this type of hydrogen, but several areas have already been identified with large accumulations of natural hydrogen in quantities that could dramatically change the possibilities for its use in the future.

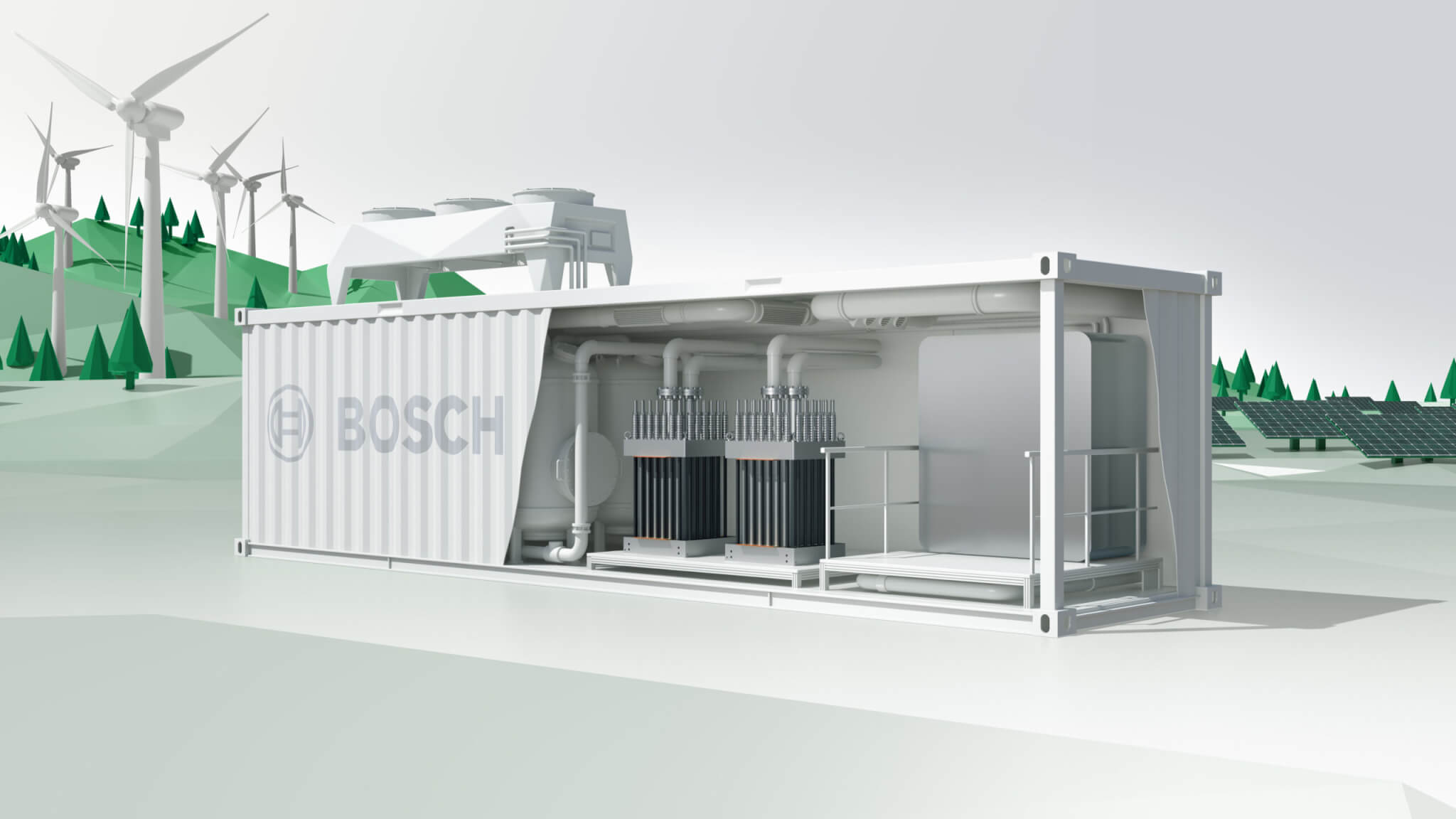

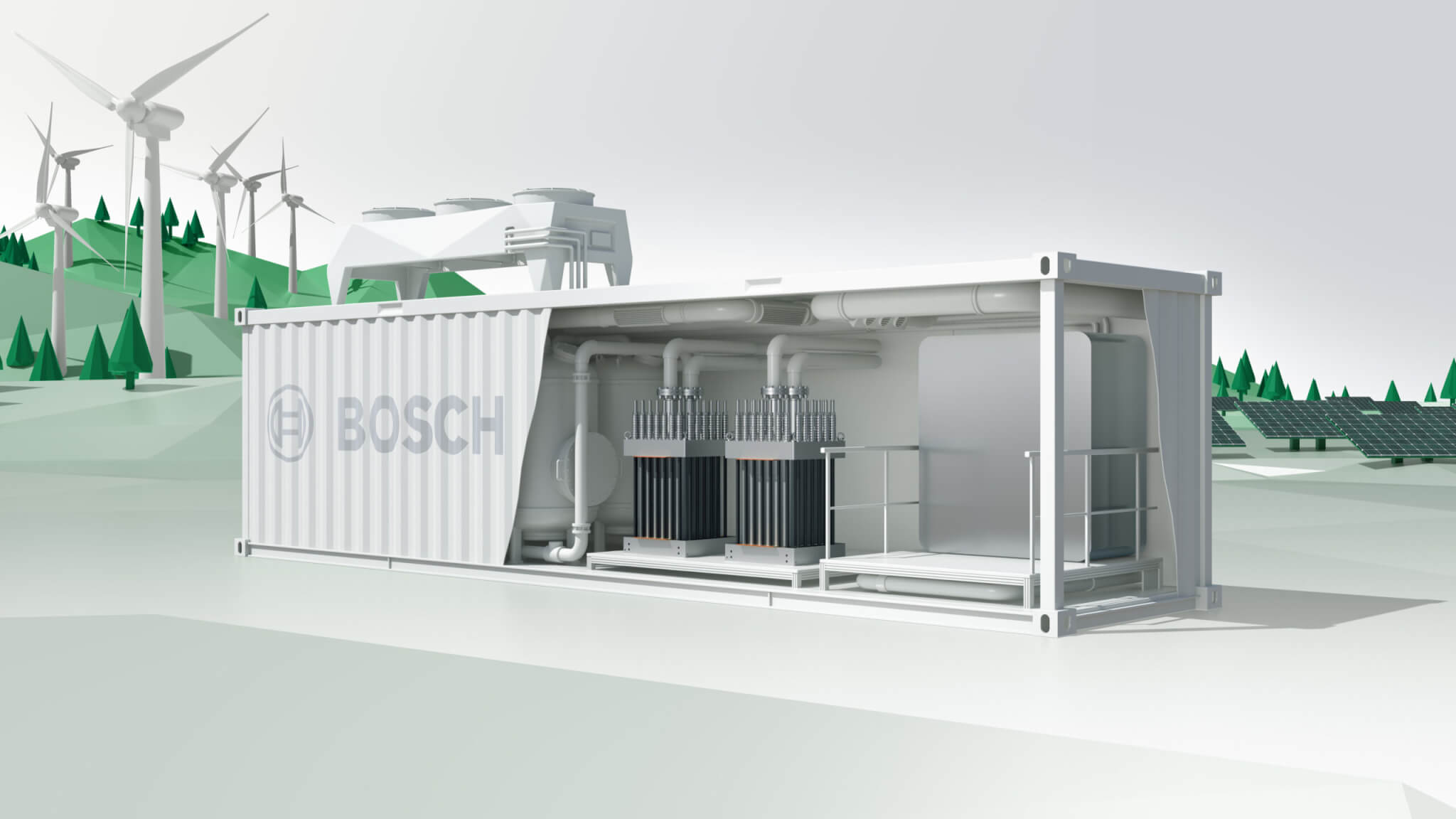

Bosch is preparing to produce containers that concentrate hydrogen production from water purification to electrolysis in one place. | Graphic: Bosch

How Bosch sees it

It is important for the automotive industry in the Czech Republic that the use of hydrogen in transport offers opportunities for further development even in the context of the ongoing transformation. For example, Bosch, one of the pillars of the automotive industry in the Czech Republic, is working on hydrogen technologies. Not only its production plants, but also its development and technology centres make a very important contribution.

Bosch is newly active along the entire hydrogen value chain, developing technologies for the production and use of hydrogen. In doing so, it is applying its experience from the automotive industry, including in the production of green hydrogen. More than 3,000 people work on hydrogen technology projects at Bosch, more than half of them in Europe, including in České Budějovice, where 800 engineers and technicians are dedicated to cutting-edge technologies for various future mobility solutions, including hydrogen.

The development of hydrogen technology at Bosch starts from the ground up, with water treatment. In České Budějovice, a unique water treatment solution for electrolysis, which is also applicable to seawater, is being developed and tested. This equipment, which can be built into a container, should be available in 2024.

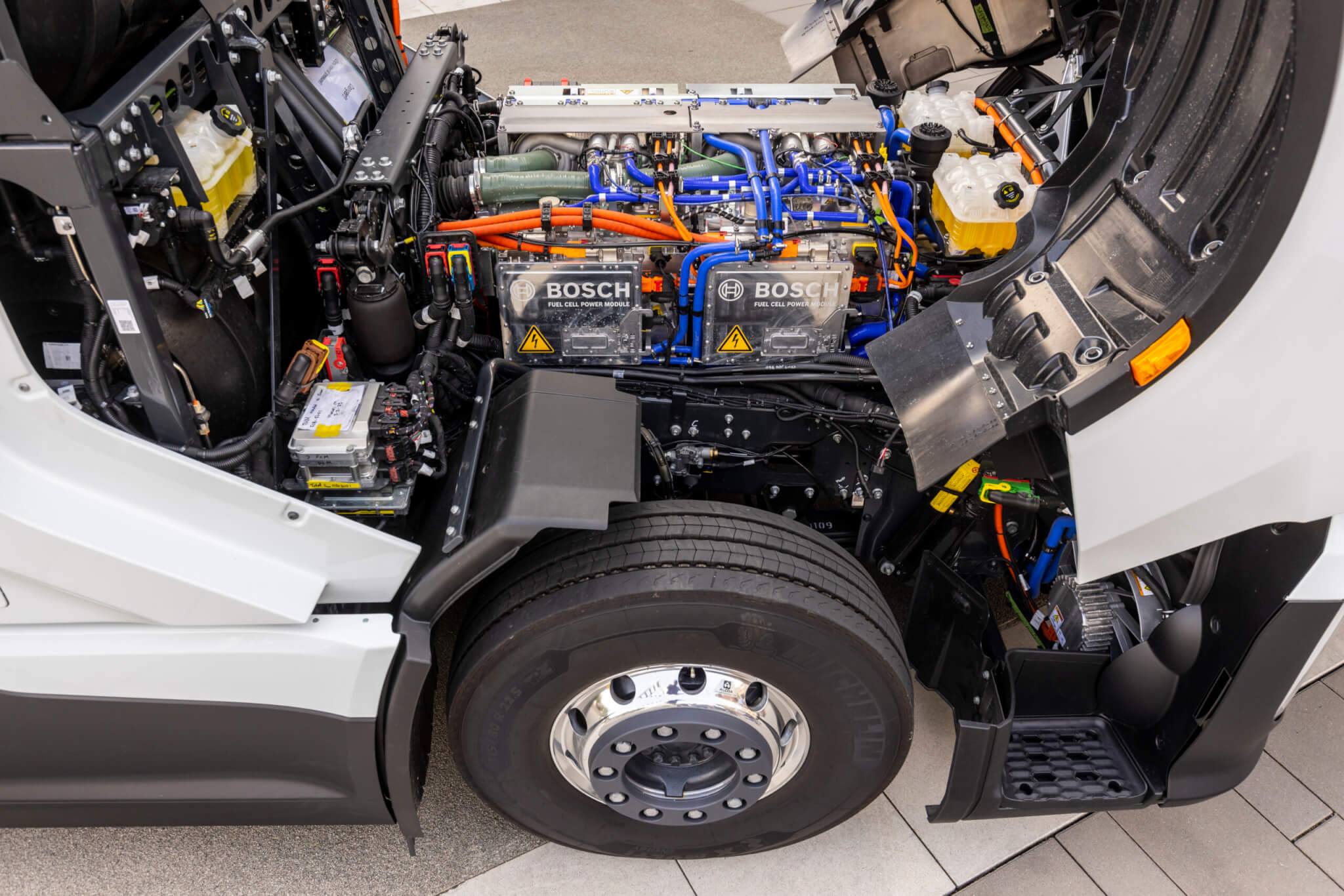

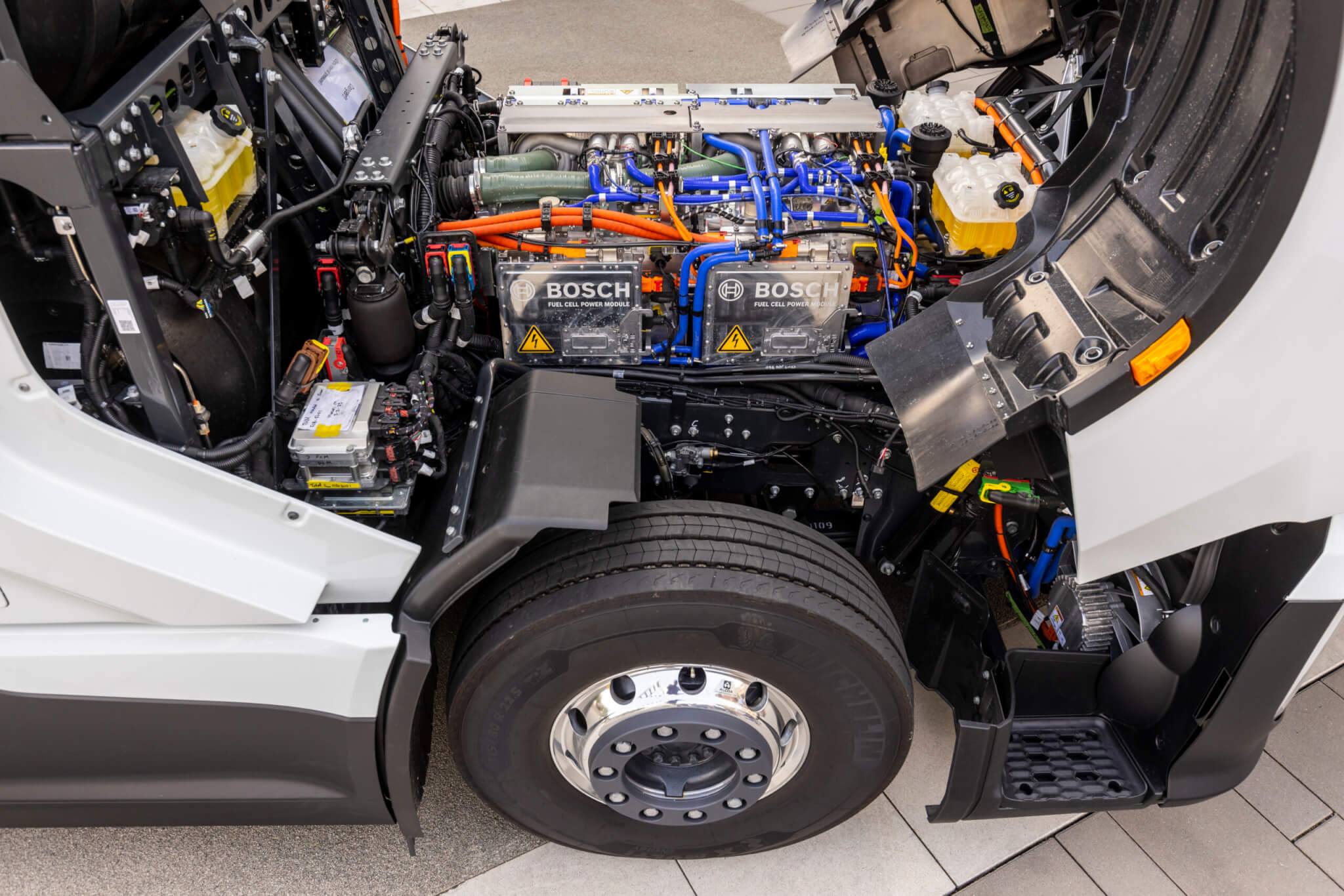

Bosch produces large fuel cell blocks for use in heavy-duty trucks. | Photo: Bosch

In České Budějovice, Bosch is also involved in the development of electrolyzers in the form of modules using PEMEL (Polymer Electrolyte Membrane Electrolysis) technology. They are prepared in a containerised arrangement in scalable sizes ranging from relatively small (1.25 to 5 MW) to large industrial solutions (10 to 1000 MW). The first prototypes are already being tested and are expected to be on the market in 2025, with Bosch having already secured its first partners. The use of these devices is ideal in conjunction with emission-free energy sources. However, the problem is that the electrolysis process cannot be interrupted, so a power source must be available for continuous operation, for example in the form of a battery pack.

In the future, Bosch is working on an innovative solution that combines everything from water purification to electrolysis in one unit. Such a plant could also be deployed, for example, in offshore wind farms, where both the electricity supply and the chemical treatment of the water are eliminated, resulting in hydrogen being piped away. In České Budějovice, as part of the development of plastics, they are also looking for materials that enable lossless storage and transport of hydrogen through pipelines.

At the cutting edge of Bosch’s hydrogen technology development are fuel cells. Few companies in the world can manufacture them. Last year, Bosch started mass production of the FCPM (Fuel Cell Power Module) at its plant in Feuerbach, Stuttgart. In its production, Bosch uses half of the components it has available from development and production for other technologies.

Refuelling hydrogen into a truck at the Bosch plant in Homburg. | Photo: Bosch

Bosch has already started supplying 216 kW fuel cell blocks for Iveco trucks. Smaller blocks of 132 or 190 kW for delivery vehicles and scalable blocks of 70 or 150 kW for light commercial vehicles are also under development. Bosch does not yet envisage a range for passenger cars. Work is currently underway to extend the life of the cells so that they retain more than 85 percent efficiency for 30,000 operating hours instead of the current 20,000.

The importance of Bosch for České Budějovice is also important in view of its cooperation with universities in the development of fuel cells and software. 50 students are currently working on research projects at the development centre.

Directly into the engine

Bosch is also exploring other applications for hydrogen. It is also working on a hydrogen-fuelled engine and developing systems for indirect and direct hydrogen injection. This solution is particularly suitable for diesel engines in heavy vehicles on long journeys with particularly heavy loads. A hydrogen engine can do everything a diesel engine can do, but is carbon neutral. Yet more than 90 percent of the necessary development and production technology is already available. The hydrogen engine is expected to be launched during 2024. Bosch already has orders for it. Deutz is also working on a similar solution for large engines.

Hydrogen is also finding applications in sports. The Automobile Club de l’Ouest (ACO), the organiser of the 24 Hours of Le Mans, is behind this activity as it seeks to make racing more sustainable. As pure electric propulsion is still out of the question for endurance racing, it has announced a category for hydrogen-powered cars for 2026. The original aim was to use fuel cells, but testing them at race pace has not yet yielded satisfactory results. That’s why space has been opened for hydrogen combustion engines. The first working prototype of such a vehicle was presented by Bosch in cooperation with Ligier Automotive. The basis is a petrol engine that the experts at Bosch Engineering have modified to burn hydrogen.

The future of not only endurance racing could be cars with hydrogen burning engines, such as the Ligier-Bosch H2E demonstration prototype. | Photo: Bosch

Toyota’s hydrogen-powered Corolla successfully competes in endurance races in Japan. Hydrogen could therefore become the basis for a future form of fossil-free motorsport.

EU on the road to the hydrogen era

In 2023, the European Parliament approved the official revised form of the Renewable Energy Directive, the so-called RED III (Renewable Energy Directive). The directive raises the European Union’s target for the share of renewables in the EU’s final energy consumption to at least 42.5 percent by 2030. The EU has also now come up with binding targets for the consumption of renewable hydrogen in the transport and industrial sectors. This directive is binding for all member states.

For the first time ever, the directive sets mandatory targets for the consumption of renewable fuels of non-biological origin, which include renewable ammonia, renewable methanol and synthetic fuels in addition to renewable hydrogen. Specifically, this means that transport will have to provide around one per cent of all energy consumed by 2030 using these non-biological fuels. This is to be achieved primarily through the consumption of renewable hydrogen. To give you an idea, 20 000 tonnes of hydrogen should be consumed in the Czech Republic in 2030.

The EU wants to produce 10 million tonnes of green hydrogen by 2030 and import another 10 million tonnes from other parts of the world. However, current global production by electrolysis is less than 300,000 tonnes. Achieving the targets will therefore require huge investments to multiply the currently small number of European electrolyzers and install 150 to 210 GW of new renewable energy capacity to power them.

The use of fuel cells is proving to be the most efficient solution for long-distance heavy goods transport, and many manufacturers, such as Iveco, are already testing such vehicles. | Photo: Iveco

The AFIR requires EU countries to build hydrogen filling stations with a capacity suitable for the development of freight transport every 200 km on the main TEN-T motorway network (i.e. on D1 or D5 motorways in our country) by the end of 2030.

The Czech Republic is moving forward, but slowly

The year 2023 was also important for the development of hydrogen transport in the Czech Republic. Orlen Unipetrol opened the first two public filling stations in Prague, Barrandov and Litvínov. At the same time, Čepro launched another non-public station in Mstětice near Prague. Together with the first hydrogen filling station, which was established more than two years ago in Ostrava, this brings the Czech Republic’s total to four.

The first energy system for the industrial production of emission-free green hydrogen in the Czech Republic was put into operation by Solar Global in Napajedli. The hydrogen produced by a proton conducting membrane electrolyzer using a photovoltaic power plant supported by wind energy in full green mode will produce eight thousand kilograms of emission-free hydrogen per year.

Since last summer, the Prague City Transport Company has been testing a bus with fuel cells from Škoda Electric, and the Orlen Unipetrol group has been testing a similar bus developed by the Slovak company Mobility&Innovation Production in Most and Litvínov.

ČEPRO in Mstětice near Prague in the presence of the Ministers of Finance Zbyněk Stanjura and Transport Martin Kupka inaugurated the fourth hydrogen filling station in the Czech Republic. | Photo: ČEPRO

This year, among other things, the CEZ electrolyser project will continue, which will offer a filling station for ten hydrogen buses serving part of the Central Bohemian Region in the vicinity of Mníšek pod Brdy.

This year, the Ministry of Regional Development is due to finalise the Czech Hydrogen Strategy and new calls for support for renewable hydrogen production from the Modernisation Fund under the GreenGas programme should also be announced. Further subsidy calls for the acquisition of filling stations will be under the responsibility of the Ministry of Transport.

The hydrogen bus Škoda H’City was tested by the Transport Company of the Capital City of Prague. Prague City Transport in cooperation with Škoda Group and Orlen Unipetrol. | Photo: Vladimír Rybecký

An updated version of the National Action Plan for Clean Mobility is also due to be released this year. According to the current one, there should be 12 hydrogen stations in the Czech Republic by 2025 and 40 stations by 2030.

Contact

Next articles and interviews

Next articles and interviews

+ Show